High-Performance Lube & Hydraulic Oil Filtration Solutions

Effective filtration is critical for maintaining the reliability and longevity of industrial equipment. Contaminants in lube and hydraulic oil can lead to increased wear, reduced efficiency, and unexpected equipment failures. Protecting rotating components and hydraulic systems from these threats is essential for minimizing unscheduled maintenance and costly downtime.

With decades of expertise, Kaydon Filtration is a trusted leader in designing advanced oil filtration solutions that safeguard critical assets.

Protecting Equipment with Advanced Oil Filtration Technology

Engineered for Demanding Industrial Environments

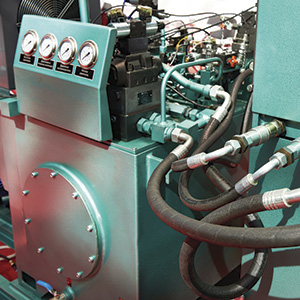

Our solutions deliver robust, high-efficiency particulate and water removal for lube and hydraulic oil applications. These systems protect critical components from harmful contamination, minimize equipment wear, and support reliable, long-term operation.

Related Products

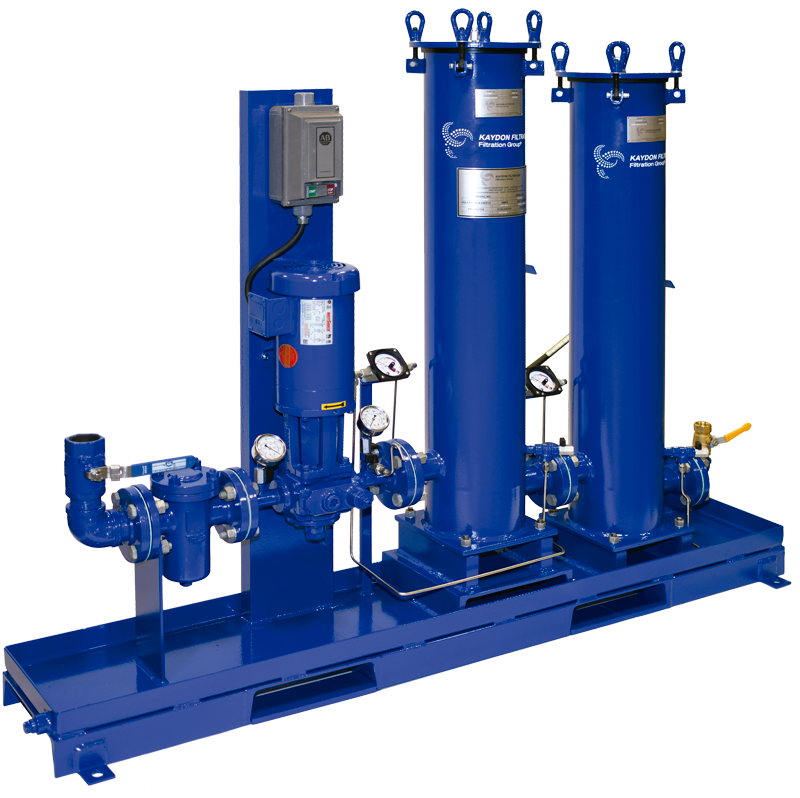

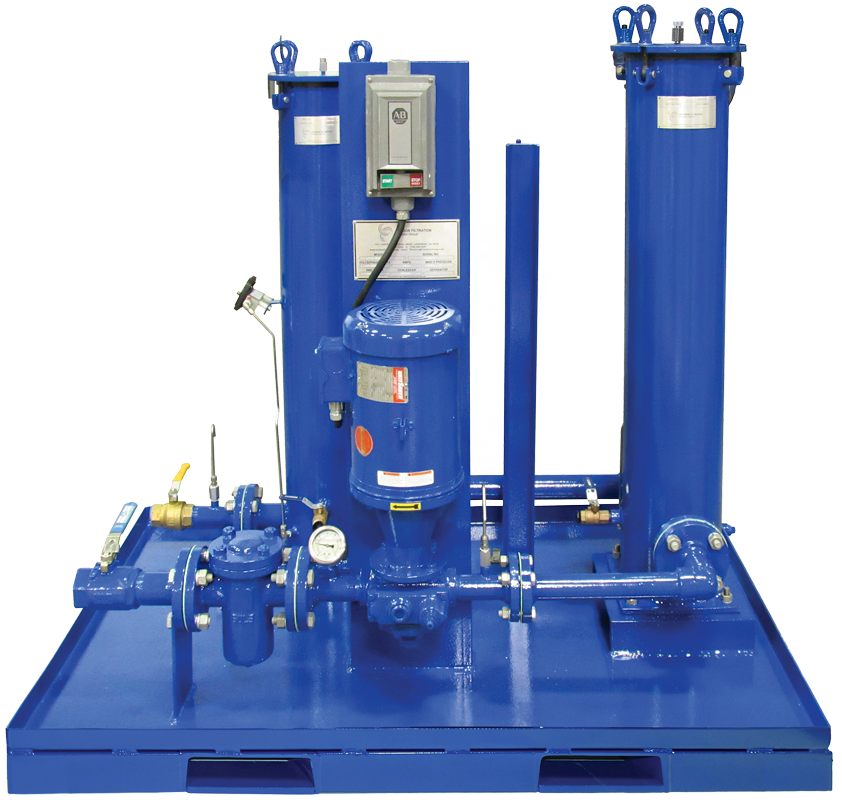

KP Series Filtration Systems

The KP Series sets the standard for industrial oil filtration, delivering continuous removal of harmful particulates and water to safeguard critical equipment and maximize uptime.

- High-efficiency contaminant removal: Efficiently eliminates particulates and water from lube and hydraulic oils, reducing the risk of equipment wear and unplanned maintenance

- Continuous protection: Designed for around-the-clock operation, supporting long-term reliability in demanding industrial environments

- Versatile application: Proven performance in steel and aluminum mills, paper mills, and other heavy industries where oil cleanliness is critical

- Rapid oil conditioning: Quickly restores oil quality during shutdowns, preparing systems for efficient and trouble-free startup

- Customizable solutions: Available with a range of options and configurations to meet specific operational requirements

The KP Series ensures your lubrication and hydraulic systems operate at peak performance-minimizing downtime, extending equipment life, and delivering confidence in every run.

In-line Filter Housing

981 Series

- High-Performance Filtration: Designed for reliable, high-pressure inline filtration in hydraulic and lube oil systems, supporting flows up to 20 gpm and pressures up to 1,200 psig

- Compact & Rugged: Ideal for mobile equipment, small hydraulic power units, and lube systems where larger assemblies aren’t practical

- Superior Protection: Offers a more robust and durable alternative to spin-on filters, providing enhanced protection for critical components

- Flexible Design: Accommodates 4-inch filter elements with multiple micron ratings for tailored particulate removal

The Model 981 delivers dependable filtration performance in a reduced footprint, helping extend equipment life and reduce the risk of oil-related failures and unplanned maintenance.