Power Plants

Since 1943, Kaydon Filtration has safeguarded critical equipment in power generation facilities worldwide. Our innovative fluid conditioning solutions ensure optimal performance and longevity of vital machinery, keeping your plant operating efficiently, reliably, and at peak capacity.

Ready to safeguard your power plant’s reliability?

Applications

Steam Turbine Oil Conditioning

Our TURBO-TOC® systems employ advanced coalescing technology to efficiently remove water, particulates, and other contaminants from turbine oil.

By keeping oil clean and dry, these systems:

- Extend turbine oil life

- Significantly reduce pump and bearing failures

- Minimize forced outages due to equipment malfunction

Available in multiple models to accommodate reservoirs up to 12,000 gallons,

TURBO-TOC® technology removes water twice as fast as competitive technologies, enhancing equipment efficiency and reducing maintenance costs.

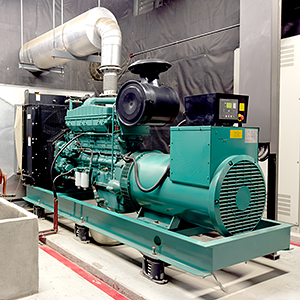

Critical Fuel Systems

Our Critical Fuel Systems deliver contaminate-free fuel to backup generators in mission-critical applications, ensuring the reliability of the world’s most advanced diesel engines.

These advanced solutions:

- Combat water contamination, microbial growth, and premature fuel degradation

- Maintain fuel quality standards during high usage events

- Accommodate green fuel products such as HVO and Biodiesel blends

Whether used for continuous bulk fuel conditioning or single pass polishing during transfer, they provide a complete, economical and versatile solution.

Oily Water Separation

Our Oil Water Separators play a crucial role in environmental protection and regulatory compliance by efficiently removing free hydrocarbons from contaminated water.

These sophisticated systems:

- Leverage enhanced gravity separation techniques

- Ensure superior effluent quality

- Accommodate both gravity-fed and pumped flows

Our MPak® coalescing plates create optimal conditions for both oil coalescence and solids retention, ensuring superior separation results. Their versatile design makes them ideal for retrofitting existing systems or designing new installations.