Steam Turbine Oil Conditioning & Water Removal Systems

Since 1943, Kaydon Filtration has been the industry leader in steam turbine oil conditioning, setting the benchmark for reliability and performance across mission-critical applications. Our proven systems deliver exceptional oil cleanliness, extend turbine life, and minimize costly downtime—trusted worldwide for over eight decades to protect the most valuable turbine assets.

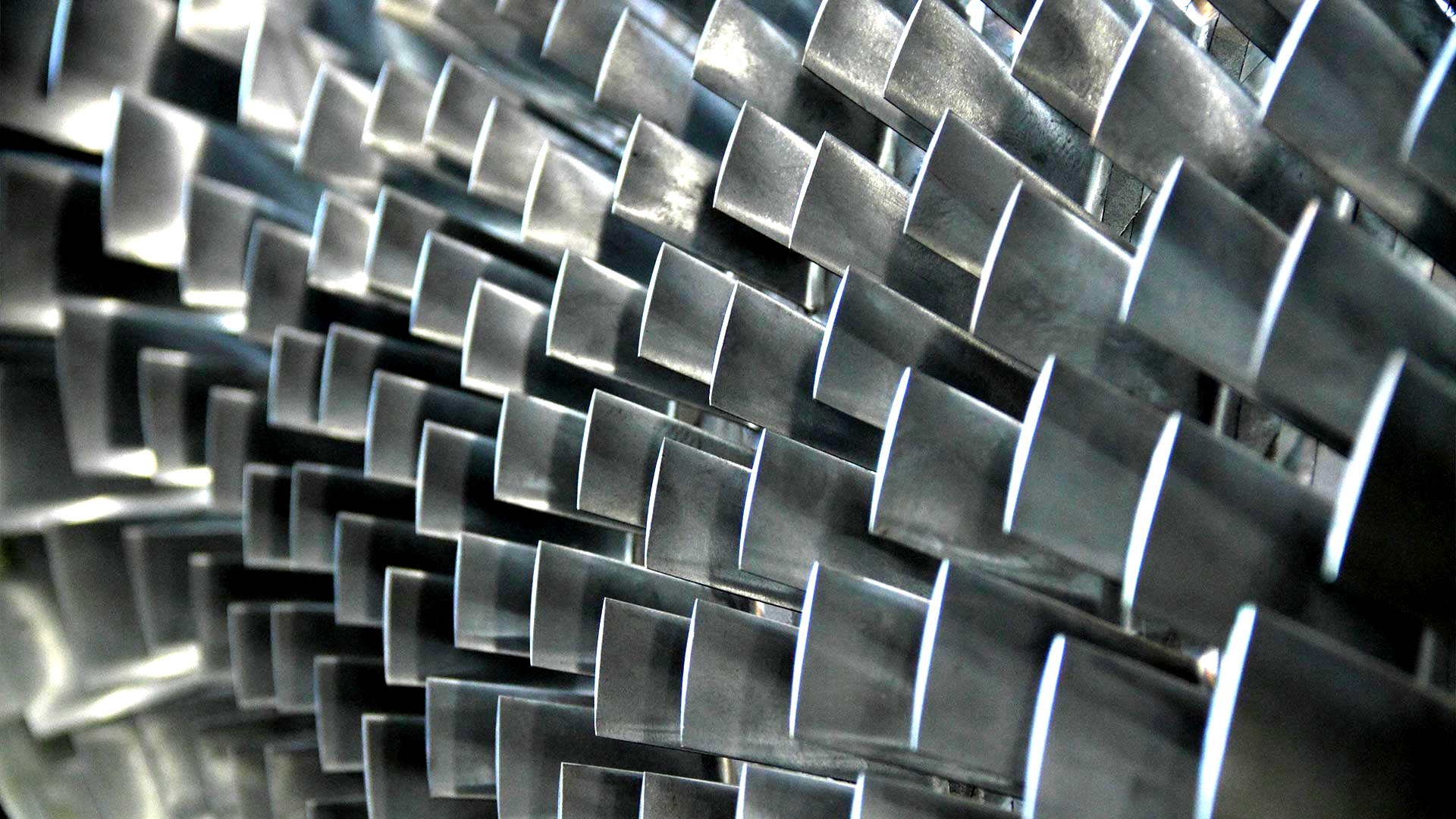

High-Efficiency Oil Conditioning for Reliable Turbine Performance

The most efficient conditioning system in the market for water removal, TURBO-TOC® removes 100% of damaging water from turbine oil and reduces Total Water Content to 100 ppm (0 ppm free, 0 ppm emulsified, 100 ppm dissolved).

Engineered for high-efficiency fluid conditioning

TURBO-TOC® systems deliver 99% removal of free and emulsified water in a single pass, reducing total water content to below 100 ppm. Designed for continuous-duty operation, units provide variable flow rates—up to 125 gpm—enabling multiple reservoir turnovers per day depending on system size and oil temperature.

This high-frequency circulation supports rapid decontamination, especially after seal failures or water ingress events. TURBO-TOC® units consistently achieve ISO 15/13/11 cleanliness levels and restore turbine oil to “clear and bright” condition, minimizing the risk of varnish formation, bearing wear, and unplanned outages.

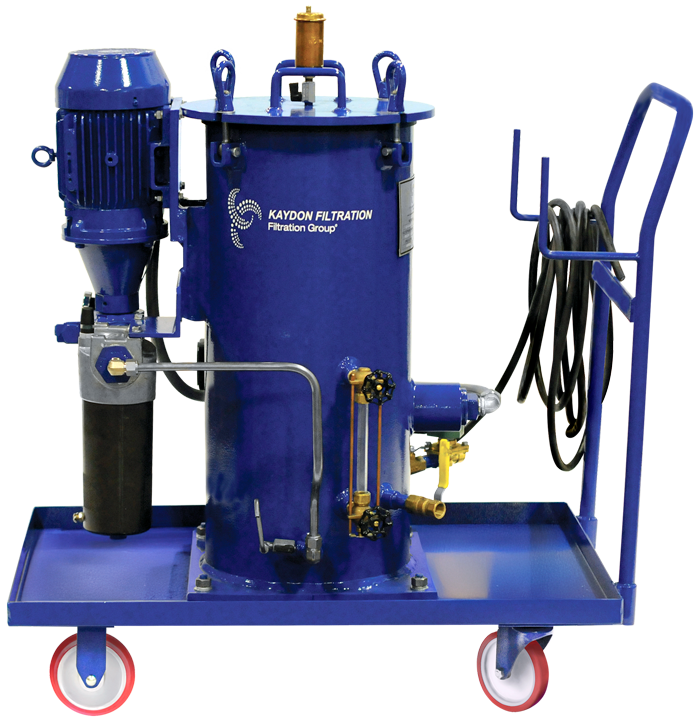

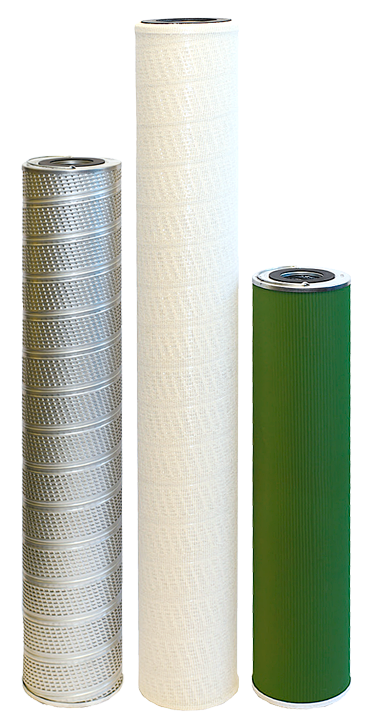

Related Products

LONGER

TURBINE LIFE

TURBO-TOC® continuously removes harmful contaminates, keeping your oil system flushed and increasing reliability.

REDUCED BEARING

FAILURE

When both water and particulate are brought down to acceptable levels, bearing failures are eliminated.

FEWER FORCED

OUTAGES

A continuous flow filtration system efficiently removes contamination, preventing forced outages.

LESS-COSTLY TURBINE REBUILDS

Clean turbine oil increases turbine dependability and helps reduce repair costs directly associated with contaminated oil.

Interested in a Flexible, Cost-Effective Solution?

Take advantage of our Rental Program and get immediate access to industry-leading oil conditioning systems without the long-term commitment. Our rental options let you quickly deploy high-efficiency TURBO-TOC® technology for planned maintenance, rapid response to contamination events, or short-term projects. Enjoy the benefits of advanced oil cleanliness, reduced downtime, and expert support, all while optimizing your budget and operational flexibility.