Filtration Elements: New & Replacement Parts Solutions

Filtration Elements for Reliable Performance

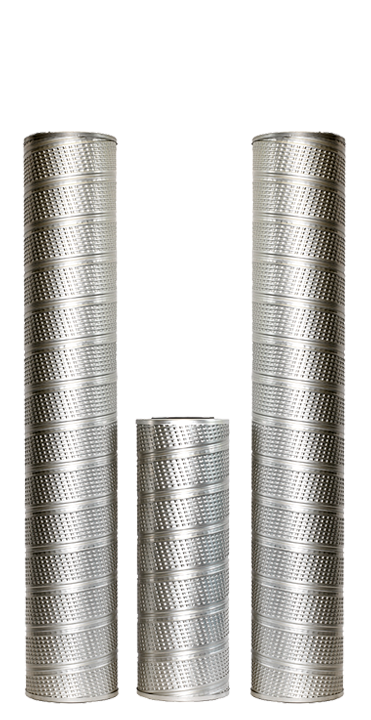

TURBO-TOC® ELEMENTS

TURBO-TOC® Turbine Oil Conditioning Elements are designed exclusively for TURBO-TOC® systems, delivering exceptionally clean and dry turbine oil. Kaydon’s integrated filtration, coalescer, and separator elements provide superior particle and water removal.

- Particulate Elements: TURBO-TOC® particulate filters are engineered to remove fine solid contaminants from turbine oil systems with high efficiency. These filters support aggressive ISO Cleanliness Code targets and protect sensitive bearing surfaces, enabling extended oil service intervals and reducing unplanned maintenance.

- Coalescer/Separator Elements: The coalescer and separator elements in the TURBO-TOC® system work together to remove free and emulsified water from turbine oil without chemicals or heat. The coalescer aggregates dispersed water into large droplets, while the separator blocks re-entry into the system—keeping oil dry, equipment protected, and startups reliable.

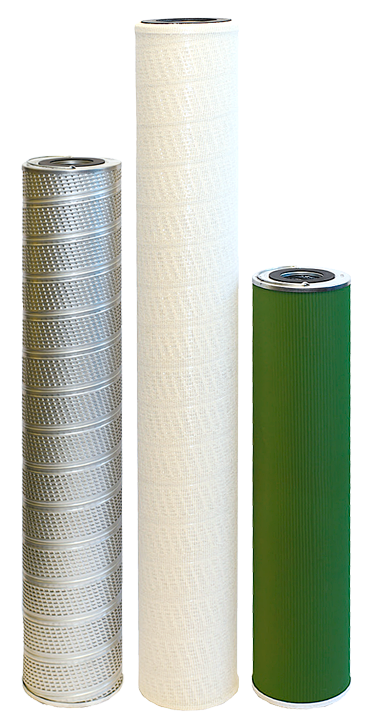

CRITICAL FUEL SYSTEMS ELEMENTS

Critical Fuel Systems elements deliver contaminate-free fuel to backup generators in mission-critical applications, ensuring the reliability of the world’s most advanced diesel engines.

- Particulate Elements: High-efficiency particulate filters are designed to remove fine solids that contribute to injector wear and poor combustion. With advanced microglass media, these filters exceed ISO cleanliness targets and extend the life of diesel-powered equipment. Their durable, highcapacity design supports long service intervals with minimal pressure drop.

- Coalescer/Separator Elements: A two-stage coalescing and separation process removes free and emulsified water from diesel fuel. CFS elements ensure water levels are reduced to below 100 ppm, protecting against microbial growth, fuel instability, and corrosion in downstream components.

DIESEL PURIFICATION ELEMENTS

Our Diesel Purification elements deliver clean, water-free fuel to critical equipment in demanding environments.

- Particulate Elements: These elements provide critical protection in bulk diesel storage and transfer systems by removing abrasive solid contaminants that cause injector wear and fuel system damage. With high-efficiency microglass media, these filters support cleaner combustion, reduced engine downtime, and compliance with modern diesel cleanliness standards.

- Coalescer/Separator Elements: Engineered for bulk diesel purification, these elements deliver effective two-stage water removal without the need for additives or heat. The coalescer collects and merges dispersed water into larger droplets, while the separator prevents re-entrainment—ensuring clean, dry fuel ready for efficient combustion and long-term storage stability.

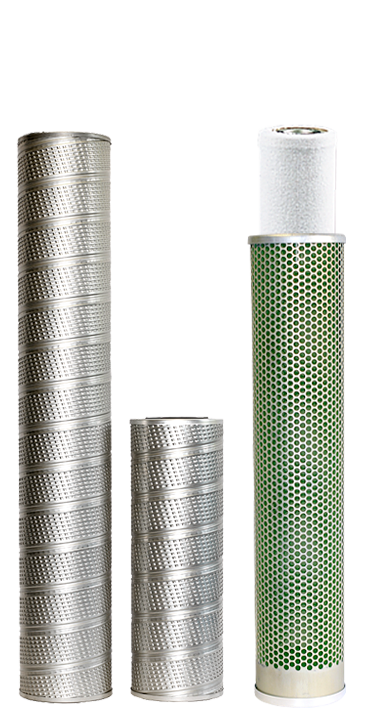

LUBE & HYDRAULIC OIL ELEMENTS

Our Lube & Hydraulic Oil elements deliver robust, high-efficiency particulate and water removal.

- Particulate Elements: Kaymax® particulate elements are designed for critical lubricating oil applications where high-efficiency particulate removal and long service life are essential. Constructed with bonded fixed-pore micro-fiberglass media, these elements maintain pleat integrity under high viscosity and flow conditions—delivering consistent filtration performance that protects rotating equipment and extends oil life.

- Absorbing Elements: Kaydri® absorbing elements are engineered for efficient water removal using quick-dry absorptive polymer technology. Ideal for systems where coalescers or vacuum dehydrators are impractical, these elements capture and retain water within the media to prevent recontamination. In addition to removing up to 1 gallon of water per element, these filters also provide 5-micron particulate filtration for comprehensive fuel cleanliness.