Industrial Filtration Systems for Reliable Operations

Kaydon Filtration delivers innovative solutions that enhance operational efficiency, extend equipment life, and ensure environmental compliance across diverse industrial applications. Our advanced filtration systems are designed to meet the unique challenges of heavy industry, protecting critical machinery and processes.

Ready to optimize your industrial operations?

The Critical Need for Filtration in Industrial Operations

Industrial environments expose fluids and equipment to conditions that accelerate contamination. Effective filtration requires both durability and high-capacity contaminant removal to protect critical systems.

Related Products

Balancing Efficiency and Environmental Standards

Industrial processes demand consistent performance while meeting operational standards. Clean fluids support better energy efficiency, protect mechanical systems, and help maintain smooth, dependable operation, without sacrificing throughput or productivity.

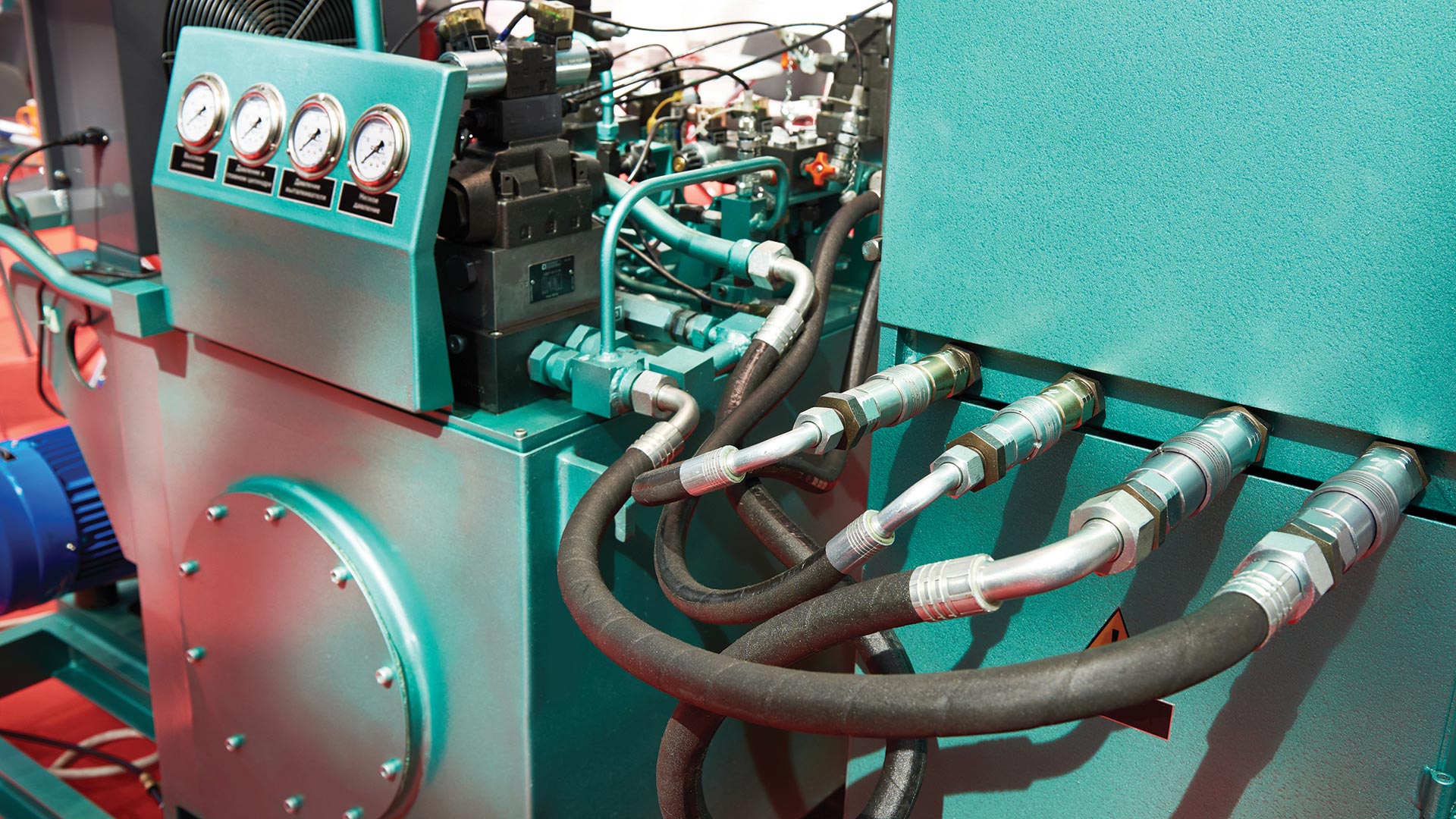

Contaminant Control in Harsh Environments

Industrial facilities operate under intense heat, pressure fluctuations, dust, and corrosive materials, all of which introduce contaminants into fuel, oils, and process fluids. Without proper filtration, these contaminants circulate through equipment and increase wear. Advanced industrial filtration systems maintain fluid integrity and help prevent costly equipment failures.

Protecting Equipment from Downtime

Even small amounts of particulate, water, or sludge can cause premature component wear, hydraulic inefficiency, or engine performance issues. Conditioning fluids upstream reduces the load on onboard filters, minimizes unplanned shutdowns, and helps equipment operate longer between service intervals.

Primary Metals

From steel mills to aluminum smelters, primary metals production requires resilient filtration systems to handle extreme temperatures and abrasive contaminants. Our specialized filtration and conditioning systems are engineered to withstand these demanding conditions, protecting vital equipment and supporting efficient, reliable operations.

Pulp & Paper

Pulp and paper production demands robust filtration systems to manage high-moisture environments and organic contaminants. Our advanced filtration and conditioning solutions are tailored to these challenging conditions, safeguarding critical equipment, enhancing process efficiency, and supporting compliance with strict environmental regulations.

Comprehensive Industrial Filtration Systems & Solutions

Engineered for High-Performance Environments

Industrial operations push equipment to its limits. Kaydon designs filtration and conditioning systems with rugged materials and reinforced construction to perform reliably under extreme temperatures, high contaminant loads, and variable operating conditions.

Fuel and Oil Conditioning Expertise

Diesel fuel and lubricants degrade rapidly when exposed to water, particulate, or microbial contamination. Kaydon’s industrial fuel filtration and oil conditioning systems:

- Remove water, particulate, and sludge from bulk fuel storage

- Protect pumps, injectors, hydraulic components, and rotating equipment

- Extend fluid life and reduce unplanned maintenance

- Improve fuel quality before it reaches the equipment

By conditioning fuels and oils at the source, our systems help maintain consistent performance across industrial operations.

Custom Solutions for Complex Processes

Every industrial operation has different fluid requirements, flow rates, and contamination challenges. Kaydon engineers custom filtration systems that integrate with your process, whether you’re managing multi-phase separation, high solids loading, or sensitive equipment. Each solution is designed to provide consistent, long-term performance.

Custom Filtration Solutions for Industrial Applications

Our custom-engineered filtration systems address contamination at its source, improving reliability across compressors, turbines, hydraulic systems, diesel engines, and other mission-critical equipment. Each solution is tailored to your operational demands for cleaner fluids, fewer disruptions, and better overall efficiency.

Key Benefits of Kaydon Industrial Filtration Systems

- Reliable contaminant removal across fuel and oil systems

- Extended component and equipment life

- Reduced downtime and maintenance costs

- High-capacity filtration for harsh, continuous-duty environments

- Custom configurations for unique industrial processes

Partner With Kaydon for Industrial Reliability

Industrial operations demand durable, dependable filtration. Kaydon’s solutions protect equipment, reduce maintenance, and maintain the performance required to keep your operation running efficiently and without interruption.

Additional Industrial Applications We Support

Power Generation & Utilities

Kaydon’s filtration and conditioning systems safeguard turbine oils, hydraulic fluids, and diesel used in backup power systems. Our solutions help protect assets, reduce wear, and keep critical power systems performing reliably under heavy load.

Chemical & Manufacturing Facilities

Manufacturing and chemical processing often introduce particulates, moisture, and chemical degradation into fluids. Kaydon’s industrial filtration systems maintain fluid cleanliness to support product consistency, protect machinery, and meet operational requirements for safe and stable production.

Resources

FAQs About Industrial Filtration Systems

Clean fuel and lubricants reduce wear on pumps, valves, motors, and engines. Effective filtration supports reliable operation, lowers maintenance costs, and minimizes downtime.

Industrial operations typically filter hydraulic oils, diesel fuel, lubricants, coolants, turbine oils, and various process fluids. Each fluid has different contamination risks that require targeted filtration and conditioning solutions.

Yes. Kaydon designs custom industrial filtration systems to meet the specific needs of industries such as power generation, manufacturing, transportation, and chemical processing. Each system is engineered to integrate seamlessly with existing processes and equipment.

By removing particulate, water, and sludge before they circulate through equipment, filtration reduces component wear, prevents system failures, and extends fluid life. This leads to fewer repairs and more consistent equipment availability.