Advanced Diesel Fuel Purification Solutions

With decades of expertise in fuel filtration, Kaydon Filtration delivers advanced solutions that deliver clean, water-free fuel to critical equipment in demanding environments. Our advanced systems are trusted worldwide to protect engines, reduce downtime, and ensure reliable performance—no matter the application.

Engineered for Clean, Reliable Diesel

Modern diesel engines require fuel that meets the highest standards for cleanliness and dryness. Even small amounts of water or particulate contamination can cause injector fouling, corrosion, and costly equipment failures.

Kaydon’s diesel fuel purification solutions are engineered to remove water, sediment, and debris—exceeding the latest ASTM and OEM requirements for fuel quality.

Related Products

Maximized Equipment Reliability and Uptime

Clean diesel reduces the risk of unexpected breakdowns and ensures critical equipment runs when it’s needed most.

Lower Maintenance Costs and Extended Equipment Life

By eliminating contaminants that cause corrosion and wear, clean diesel extends the life of fuel system components and reduces the frequency and cost of repairs and maintenance.

Improved Fuel Efficiency and Performance

Clean diesel enables more complete combustion, resulting in better fuel economy, more power, and smoother equipment operation—saving money on fuel and boosting productivity.

Fuel/Water Separation

Preventing Water Contamination to Preserve Diesel Equipment Reliability

Water contamination threatens diesel equipment with corrosion, injector damage, and costly failures.

Reliable water removal safeguards fuel systems and critical components, reducing the risk of unexpected downtime. Proactive protection minimizes maintenance burdens and preserves operational continuity.

Single Pass Vessel

851E Series

Kaydon’s 851E filters utilize advanced coalescing technology to remove water and harmful particulates, ensuring delivery of clean diesel fuel and preventing costly damage and downtime. By efficiently eliminating contaminants, they extend component life and maintain diesel equipment performance—ideal for avoiding revenue loss from fuel-related failures.

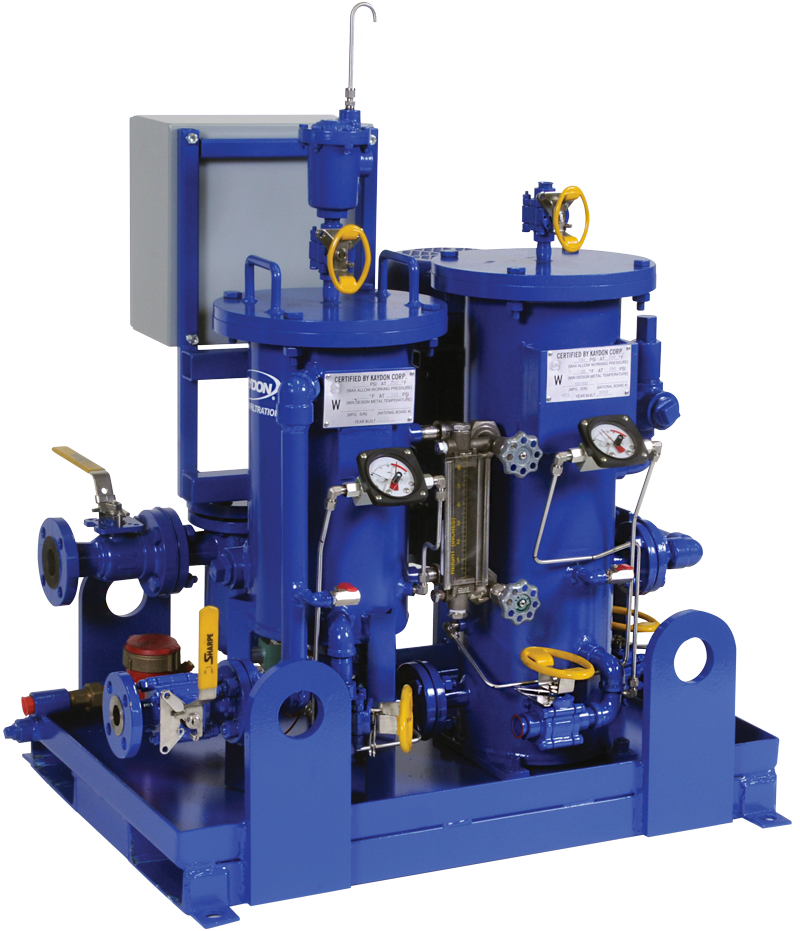

Recirculation Skid

MS Series

The MS Series Recirculation Skid combines particulate removal and water separation to remove 100% of damaging water and maintain fuel cleanliness far exceeding industry standards.

This packaged solution uses an integrated pump to continuously polish bulk storage tanks, ensuring fuel life and protecting critical engine components.

See the Technology in Action

Particulate Filtration

Particulate contamination puts diesel equipment at risk of breakdowns and costly repairs.

Advanced filtration protects vital components, ensuring consistent performance and maximum up-time.

VKS Series

Designed and built to ASME Section VIII standards, the VKS fuel filtration filter assemblies provide rugged, code-compliant filtration performance for applications requiring certified pressure vessels. Ideal for regulated environments, it includes inlet/outlet gauges, a Coast Guard-compliant configuration, and ships with a high-efficiency Kaydon filter element.

V Series

The V particulate vessels offer the same dependable filtration performance in a streamlined, non-code-stamped design that’s stocked for quick delivery.

Built from carbon steel with a compact footprint, it’s an excellent choice for cost-sensitive projects where ASME certification is not required.